Any discussion about octane invariably leads to statements from some cars’ owners that their engine performs better when they use the 91 or 93 (or higher) fuel blends in their vehicles.

For most modern, computer-controlled cars on the road today, this perception is more mental than it is factual. For classic car owners, octane can make a difference from an engine-efficiency standpoint; however, the octane rating of your gasoline has very little to do with the horsepower or torque output of your classic engine as is often alluded to in these conversations.

Octane is simply a measure of the fuel makeup, and its tendency or resistance to cause engine knock or ping when used under duress (higher RPM). The octane index rating is not based on a quantity of a chemical in the fuel mixture, but is a measure of the efficiency of the fuel blend, expressed as a ratio, relative to the efficiency of a pure hydrocarbon, which would have an octane index rating of 100 (or 100 percent). Because gasoline is made up of many different hydrocarbons, the octane rating is a comparison of the anti-knock characteristics of the blend relative to the anti-knock characteristics of a pure hydrocarbon with a 100 percent rating. Aircraft or racing fuels have a rating above 100 because the additives in the fuel raise the efficiency beyond that of a pure hydrocarbon.

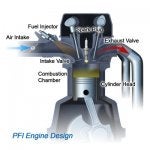

Engine knock is caused when the fuel mixture ignites too early, often before the spark plug has fired. Knock often presents itself when there is an increase in engine RPM and cylinder combustion chamber pressures are also increased. The higher the cylinder pressure, the more likely the engine will knock.

Octane is measured by operating an engine under two different conditions and averaged to result in the rating you see displayed on the pump. The first method (R) is to test the fuel mixture for its anti-knock characteristics (as a percentage of efficiency to pure hydrocarbon) when the test engine is under load, the second test (M) measures the anti-knock tendencies when the engine is free-wheeling. The average of the two results is the percentage that is shown on the pump (R+M/2).

octane_450Fuel is required to meet minimum octane efficiency standards of 87 percent to be sold at the pump, with more efficient blends having an efficiency rating of 88 percent to 90 percent considered mid-range gas. Efficiency ratings above 91 percent get the “Premium” designation. Premium gas must be, by law, at or above 91 percent, although you do also see 93 percent octane ultra-premium at many stations.

Although higher octane can cost substantially more per gallon, it does not necessarily mean it is better for your car. Higher octane gas is processed through additional steps that further refine the blend and cause it to burn more slowly than lower octanes. These additional processes are what contribute to the higher pricing, but that does not mean the higher octane will offer any advantage over other blends in many engines. Octane does not offer any better fuel mileage, increase engine horsepower, or make the engine start quicker. Higher octane only reduces the likelihood of engine knock or ping.

On modern computer-controlled cars with fuel injection, the computer is constantly monitoring fuel trim and detonation and making appropriate adjustments in the timing and fuel air mixture to compensate for engine knock. Most of these late-model engines have a sonic knock sensor installed in the cylinder block for just this reason.

As you go back in time to earlier fuel and ignition systems, the octane content becomes more important because the old point distributors and early electronic ignition distributors had only a vacuum advance to correct for engine knock. Exhaust gas recirculation systems were also in their infancy and were not as efficient as modern systems, so they had less effect on reducing knock as well.

Because higher octane gas burns slower, it is more resistant to knock when subjected to higher RPM and cylinder pressures. Compression ratios also factor into cylinder pressures. Higher ratios cause higher cylinder pressures and therefore cause the engine to be more susceptible to pre-detonation or knock.

The introduction of ethanol in fuels further complicates the octane debate. Ethanol has a higher octane rating than hydrocarbons and also ignites at much higher temperatures. Blending ethanol into pump gas will slow the combustion process and reduce the likelihood of engine knock. The delay in the ignition of the mixture, caused by the addition of ethanol, allows the fuel burn to occur while the engine piston is in the down stroke, when there is less cylinder pressure, and this reduces the likelihood of engine knock.

Ethanol can also be used as a method of increasing the octane of a fuel blend by lacing lower octane hydrocarbon-based fuels with higher octane-rated ethanol to arrive at the required octane index rating.

In summary, most modern vehicles do not require higher octane fuels, unless specifically expressed in your owner’s manual (read carefully, because there is a difference between higher octane being “recommended” and “required” in the manual). There are a few high-performance engines that were built with higher compression ratings or use higher RPM camshafts where 91 octane may be needed, but your average Subaru or V-6 Explorer will see no noticeable benefit from using the more expensive blends.

In classic V-8 muscle cars and vintage engines, a higher octane fuel is probably a good idea, but we recommend that you not buy more than you can use quickly. The disadvantages of ethanol-laced fuels are most prevalent when stored inside your gas tank over longer periods of time. The higher octane fuels are slightly less efficient than the lower grades because the retarded ignition will lead to a little less overall power and a scant fewer miles per gallon, but the reduction of wear and tear on your engine should outweigh the extra cost of the higher-rated blends.

Source:

https://www.hemmings.com/blog/2014/04/11/tech-101-octane-the-facts-and-the-fiction-behind-those-higher-priced-fuels/#comments-block